Description

THESE INSTRUCTIONS ARE PREPARED TO ASSIST TRADESMEN AND OTHERS QUALIFIED TO SERVICE LIQUID STORAGE TANK EQUIPMENT. CONSUMERS ARE NOT QUALIFIED TO PERFORM THE INSTALLATION DESCRIBED BELOW. IF YOU HAVE ANY QUESTIONS CONCERNING INSTALLATION OR OPERATION OF THE GAUGE OR GASKET, CONTACT ROCHESTER GAUGES, INC. OR ONE OF OUR AUTHORIZED DISTRIBUTORS FOR ASSISTANCE. CHECK SIDE OF GAUGE HEAD FOR MODEL NUMBER AND ASK FOR GAUGE INSTALLATION INSTRUCTIONS FOR YOUR MODEL.

How To Do The Conversion

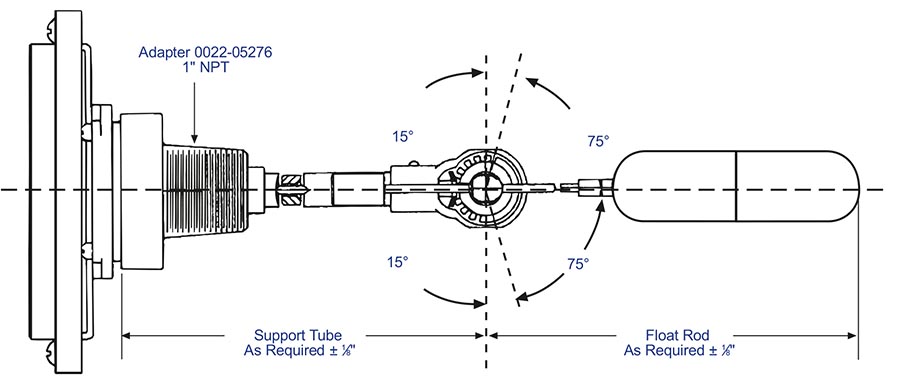

1. After the storage tank has been evacuated, remove the rotary gauge from the 1″ NPT opening at the centerline of the head. Clean and retap the female threads.

2. Remove the two screws from the bezel. Put the bezel, screws and dial chamber aside for the moment. Remove the four mounting screws holding the gauge head to the adapter.

3. Insert the lower portion of the replacement gauge, including the float bulb, float arm, gear housing and counterbalance, into the tank opening.

4. Apply three wraps of 1⁄2″ [12mm] wide Teflon tape, or other suitable thread sealant, to the 1″ NPT threads on the steel adapter through which the gauge support passes.

5. Screw the adapter into the tank opening to achieve a leak-tight joint, and align the gauge mounting holes in the horizontal plane.

6. Using the gasket and four mounting screws supplied, attach the gauge to the adapter fingertight. Be sure the gauge is right side up, the bracket tab for locating dial chamber should be on the right. Torque the mounting screws evenly to 140/150 lb.in., [16,4Nm] using a cross pattern.

7. Reattach the 4″ dial chamber and bezel to the Senior® gauge head brackets using the two screws supplied.

8. If you end up with the dial chamber upside down, you cannot solve the problem by rotating the bracket. You must rotate the entire gauge 180°.

WARNING: Even if gauge registers empty, tank may contain high pressure and flammable gas. Do not remove gauge or other pressure containing fittings unless precautions against release of tank contents have been taken. A hazard of fire or explosion may exist if proper methods are not used when removing or installing the gauge or gasket. Replace gasket if gauge is removed. Do not reuse gasket. When reinstalling gauge head align head for proper orientation of the float inside tank. Torque head or mounting screws evenly in several steps based on mounting screw size, gasket material & gauge head size & style.

CAUTION: Improper gauge selection or application may result in inaccurate gauge readings. Release of tank contents as well as damage to equipment and safety hazard may result if tank is overfilled. Fuel exhaustion may occur if tank contents are less than indicated. This gauge is not a substitute for a fixed liquid level gauge or weight measurement device that may be required for filling.

WARNING: Improper APPLICATION, installation, or use of this gauge may cause serious injury or property damage.

Materials of Construction*

Head, Gears, Gear Housing, Cros Stud, Bearings & Float

Stainless steel.

Centershaft, Support Tube & Float Rod

Stainless steel.

Drive Magnet

Alnico.

Gasket

Spiral wound, teflon filled, stainless steel.

Adaptor

Cold-rolled steel.

Counterweight

Stainless Steel

When Ordering Specify:

1. Gauge model number.

2. Tank I.D.

WARNING: Carefully ensure that gauge and adapter are adequately protected from damage that might cause leakage of tank contents.

*Materials and specifications are subject to change without notice. Pressure ratings subject to change due to temperature and other environmental considerations.