Description

General Specifications*

Mounting

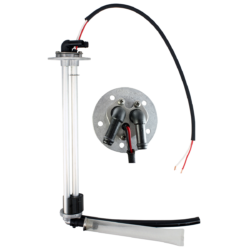

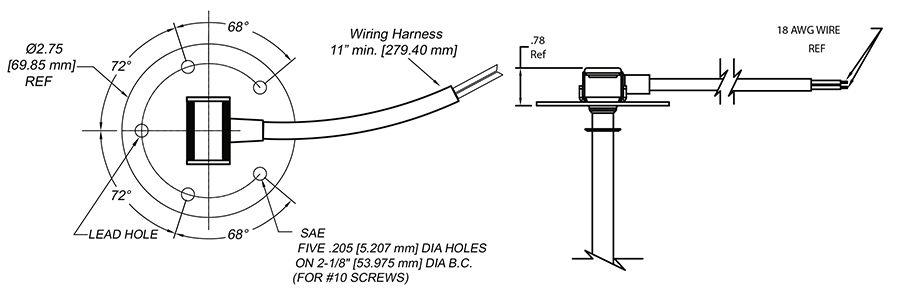

Designed for top mounting only.

Accuracy

System accuracy depends upon proper sender sizing. Resistance values are 30 ohms ±2% at full and 240 ohms ±2% at empty. System accuracy may depend upon tank shape. System accuracy may be less near full and empty. System accuracy may be less if tank is not level. System accuracy may be less depending upon indicator. This sender is not to be used for filling.

Temperature

-40°F to 176°F, -40°C to 85°C.

Power

0.5 watts maximum.

Leak Test

Passes 16 PSIG [1,1 BAR] test.

Gasoline Rocker Test

3,000,000 cycles.

Fuel Sender Testing

Meets requirements of ISO 10088, ABYC H-24, 33 CFR 183.590 and ISO 8846. Marine Industry test requirements were conducted at an independent laboratory.

Dry Bench Cycling

25,000,000 cycles.

Vibration Test

6 hours each plane, 9.9 Grms, 24-2,000 Hz.

Salt Spray Test

96 hours external as mounted.

Shock Test

1,000 cycles @ 25G peak acceleration with 8ms duration.

Fire Test

No loss of gasket seal during 2-1/2 minute fire test.

Ignition Protection Test

50 empty to full to empty cycles in explosive atmosphere without igniting.

Lead Pull Test

20 lbs. harness, 10 lbs. each wire.

Materials of Construction*

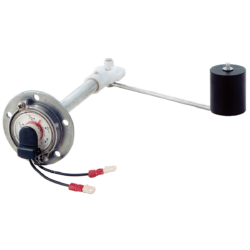

Head

Stainless steel.

Support

Stainless steel.

Float

Nitrile rubber.

Material Compliance

RoHS Compliant.

Wiring Harness

18 awg. wires.

Black & white PVC insulation.

Black overmolding PVC jacket.

Optional mounting gasket: Nitrile or Viton -please specify.

*Materials and specifications are subject to change without notice.