Description

General Specifications*

Accuracy

Accuracy depends upon proper gauge sizing. Senior dials ±7%, TwinSite dials ±12%. Accuracy may be less depending upon tank shape. Accuracy may be less near full and empty. Accuracy may be less if tank is not level. This gauge is not to be used for filling. All accuracy estimates are expressed as a percent of full scale.

Temperature

-40°F to 158°F, -40°C to 70°C.

Humidity

Point exposed portions of gauge, less dial, for marine applications.

Shock & Vibration

Suitable to mobile applications.

Power

0.5 watts maximum for TwinSite versions.

Tank Pressure

Up to 25 PSIG [1,7 Bar].

Approvals

These direct indicating gauges are UL listed for flammable liquids. Some modesl UL recognized for marine service.

Note: For installation instructions see MS-501/502 (mounting standard).

When Ordering Specify:

1. Gauge model number.

2. Tank diameter and riser height.

3. Mounting location.

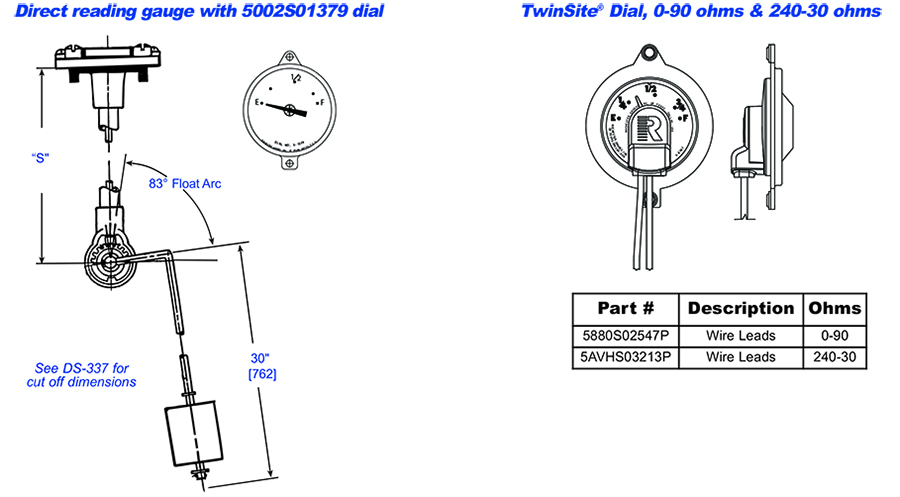

4. Ohm range on TwinSite® versions.

5. Preferred switch on switch gauges, if other than standard.

6. Any listed options or preferences.

Materials of Construction*

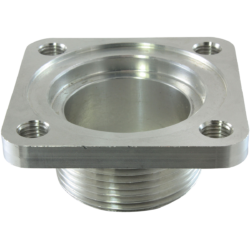

Head

Die cast aluminum.

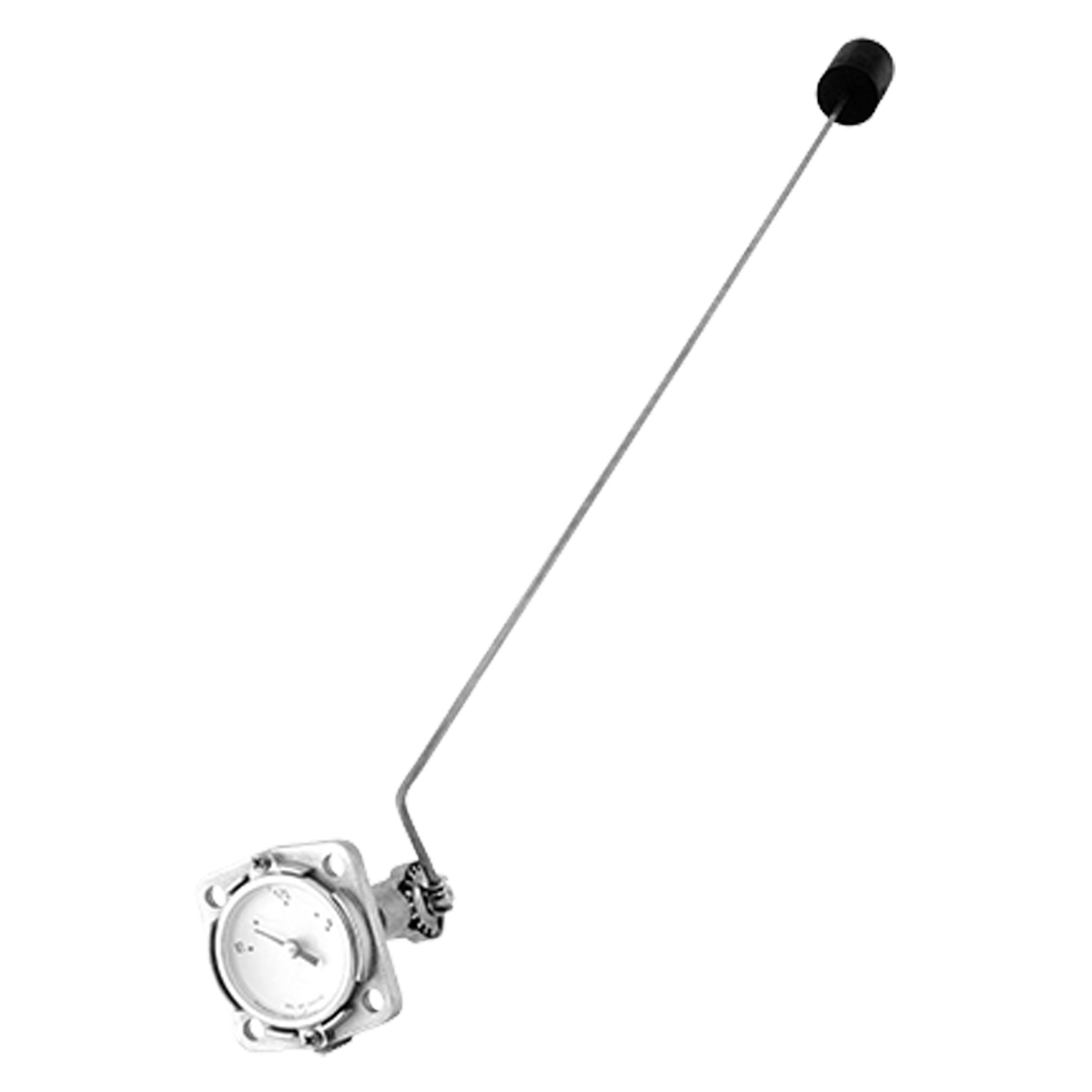

Centershaft, Support Tube & Float Rod

Tempered aluminum.

Gears, Cross Stud & Bearing

Stainless steel.

Drive Magnet

Alnico.

Gear Housing

Acetal plastic or Aluminum.

Float

Nitrile rubber.

Gasket

Buna-N, 0015-00004 or 0015-00079.

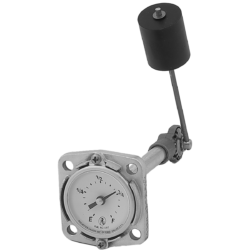

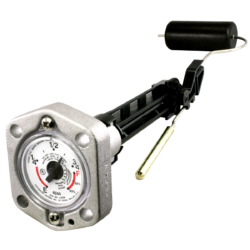

Direct Reading Dial

Aluminum with acrylic crystal, hermetically sealed.

Side Reading Dial

Aluminum with polycarbonate crystal, hermetically sealed.

TwinSite Sender

Polyamide.

Mounting Bolts

Zinc-plated steel 1/4″-28 x 9/16″ long.

*Materials and specifications are subject to change without notice. Pressure ratings subject to change due to temperature and other environmental considerations.