Description

Liquid types

Diesel, biodiesel, kerosene, petrol, water or any liquid which is compatible

with the materials of construction.

Construction

Housing: Anodised die cast aluminium.

Sensor tube: Anodised aluminium.

Wetted materials: PTFE, FVMQ, Nylon (PA66), fluorosilicone,

aluminium & stainless steel.

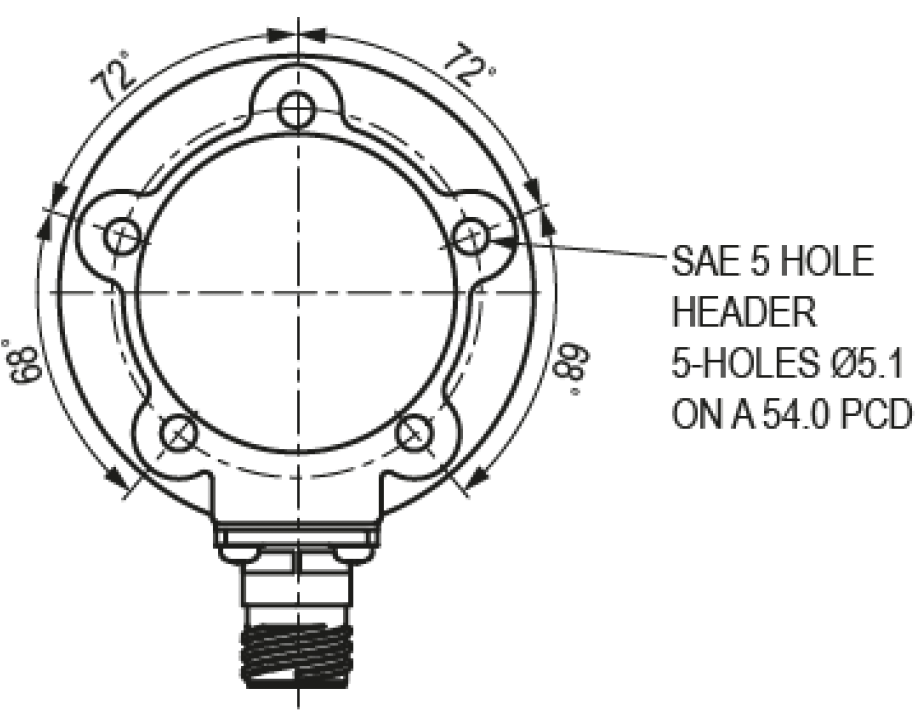

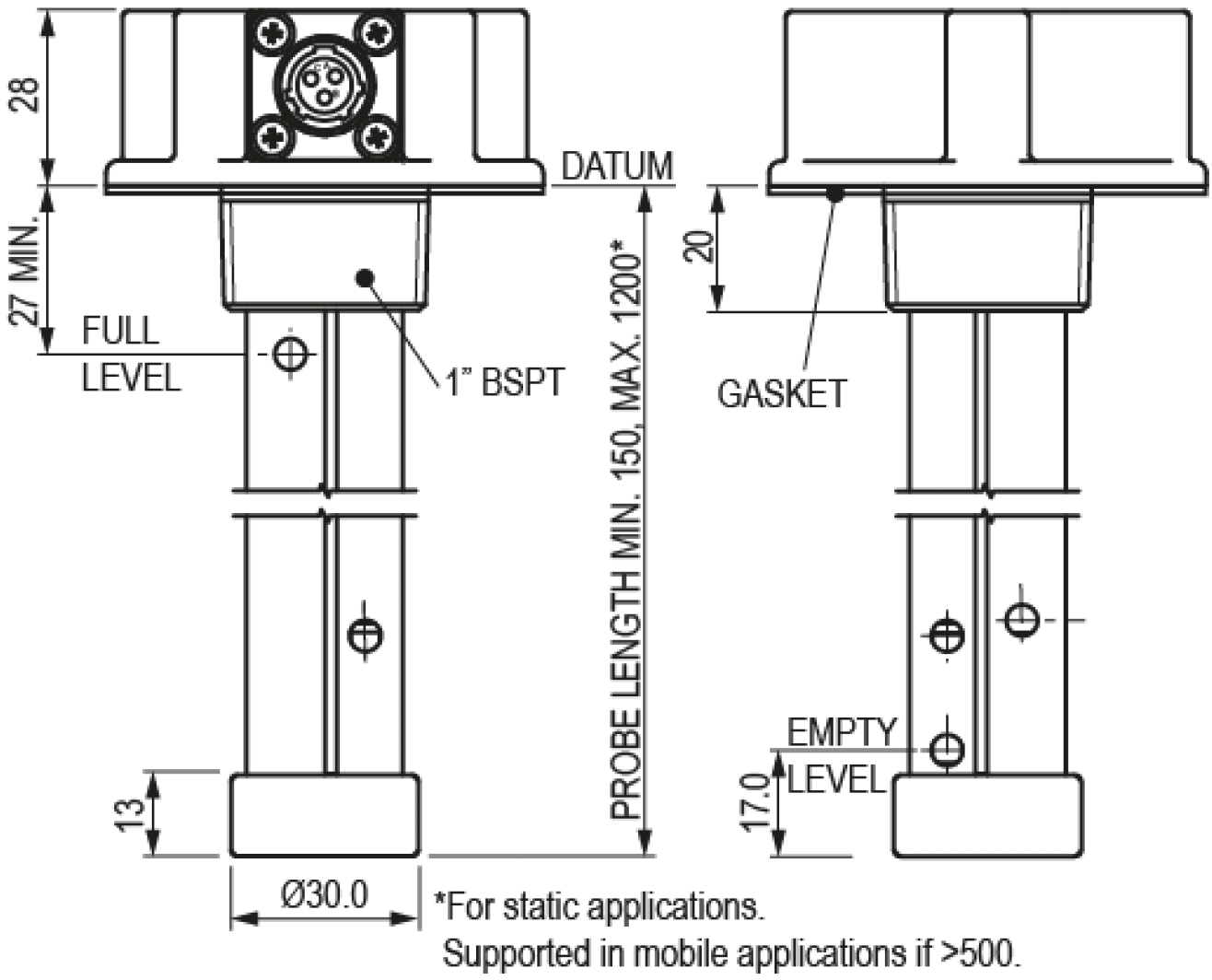

Dimensions

Probe length: Min 150 mm.

Max 1200 mm static applications,

supported in mobile applications for probe lengths greater than 500 mm.

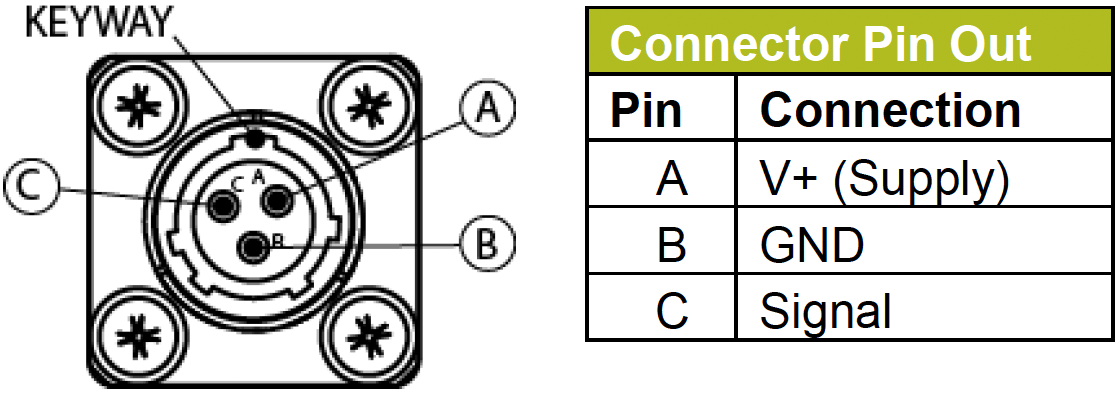

Electrical

Supply voltage: 9-36 VDC

Supply protection: 80V over voltage & reverse polarity protection.

Supply current: 15 mA@12 VDC + output load.

Connections: Military connector; D38999/20WA98PN.

Outputs

Current: 0-20 mA, 4-20 mA.

Resolution: 20 μA.

Max load: 250 Ω (Including interconnecting cable resistance).

Accuracy: ±2.0% of probe length @ 20 ºC in diesel.

Environmental Ratings

Designed to meet:

Operating Temperature: -40 ºC to +125 ºC.

Sealing: IP67.

Weight: 300 g (1000 mm long unit).

Max tank pressure: 1.7 bar (25 psi).

EMC: Type approval in accordance with EN ISO 13766:2006.

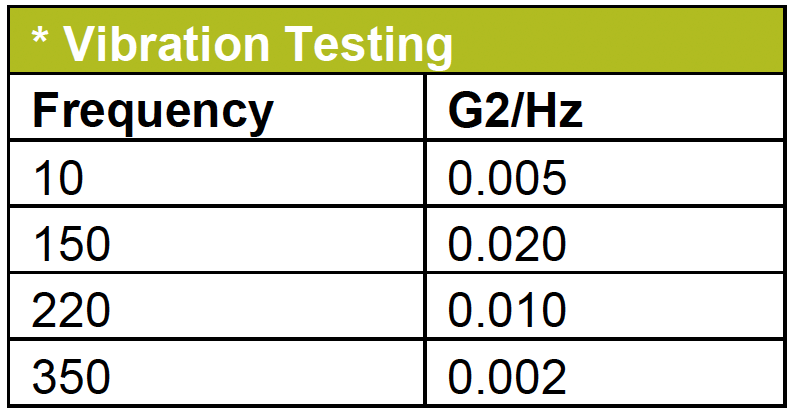

Vibration: 500 mm sensor type tested to 1.88 grms to BS EN 60068-2-64:1993*.

Shock: 500 ms-2, 11 ms to BS EN 60068-2-27:1993.

Options

Custom empty/full points: Specific full levels can be provided within the allowable measurement range of the probe.

Non-linear Tanks: Compensation for non-linear tank shapes available.