Description

Liquid Types

Liquids compatible with the construction materials, typically diesel, kerosene, petrol, water.

Suitable for fuels that contain Toluene or Ethanol.

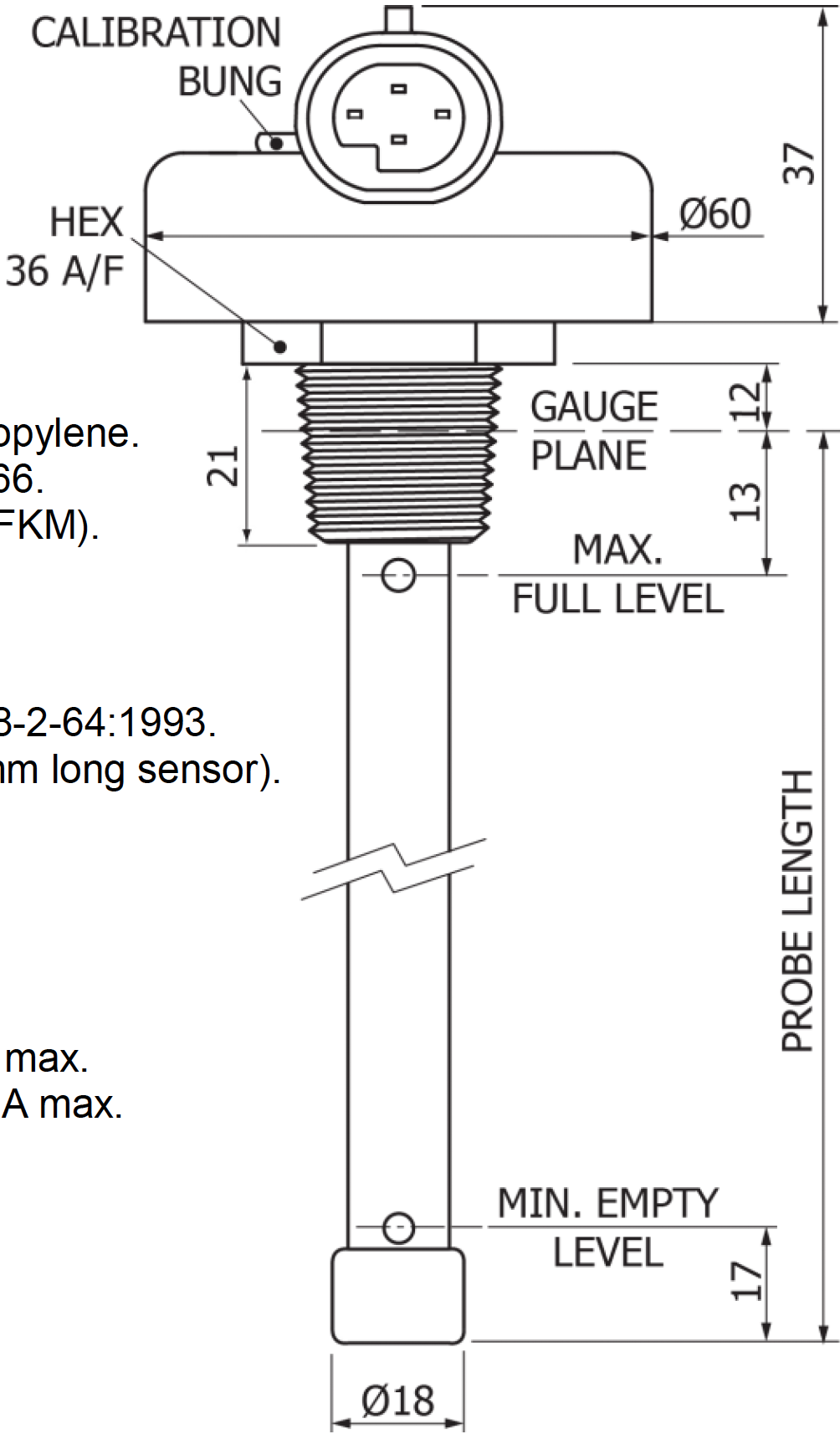

Dimensions

Probe Length: Min. 200 mm, Max. 600 mm.

Threads: ½” BSPT, 1” BSPT, ½” NPT.

Optional Flange: Fozmula F/T1 SAE 5 Hole.

Performance

Accuracy: ±2% of depth @ 20 ºC.

Materials

Enclosure: 30% glass filled nylon.

Internal Electrode: PTFE.

Sensor Tube: 316 stainless steel.

Wetted Seals: Viton (FKM).

Internal Spacers: Polypropylene.

End plug: Nylon 66.

Environmental Ratings

Sealing: IP67 with mating connector.

Max Pressure: 1 bar.

Operating Temp: -20 ºC to +85 ºC.

Shock: 50 g, 6.3 ms

Vibration: 15.3 Grms

BS EN 60068-2-64:1993.

Weight: 250 g (300 mm long sensor).

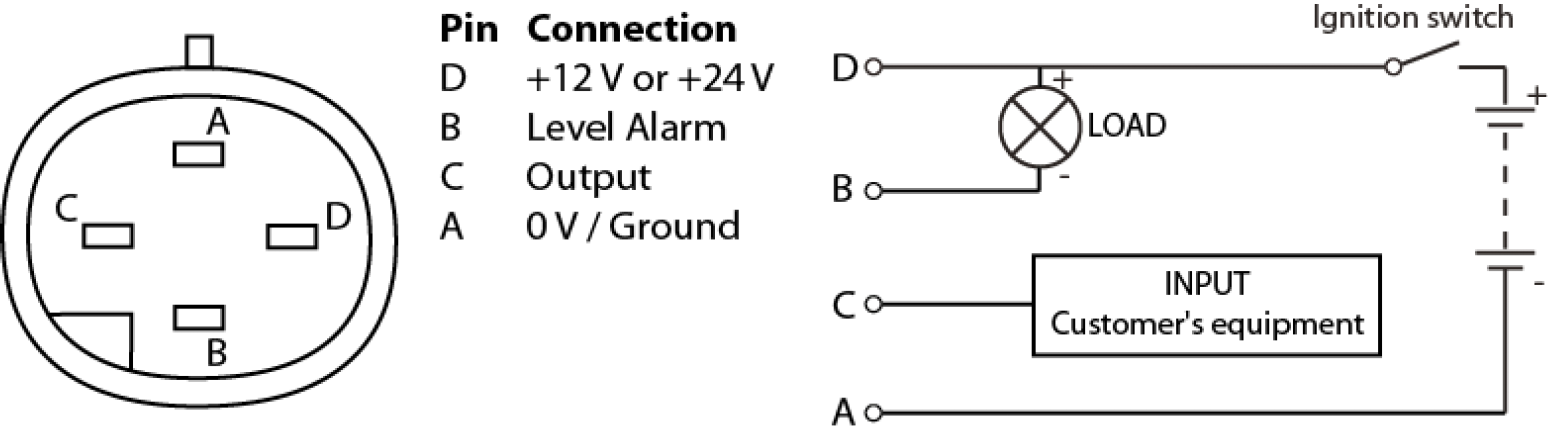

Electrical

Supply Voltage: 9-34 VDC.

Supply Current: 30 mA.

Supply Protection: Over-voltage 80 VDC for 2 minutes.

Reverse polarity.

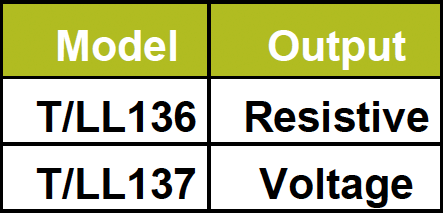

Signal Output: Resistance range; 0-250 Ω or 250-0 Ω, 2 Ω steps, 0.4 W max.

Voltage source range; 0-5 V or 5-0 V, 20 mV steps, 10 mA max.

Alarm Output: Switch to ground. Max 100 mA. High or low level.

Default setting is 12.5% of full level.

Minimum 30 mm from sensor end.

Connections: 4 Way Delphi Packard Metri-Pack 150 Series.

Mating Connector: Fozmula C/K1 (Delphi Packard Metri-Pack 150).

To fit 0.8-1.0 mm2 conductor, Ø1.6-2.15 mm sleeve.

Calibration Instructions

Units will be supplied calibrated for diesel. They can be recalibrated for alternative fuels:

Full Point:

- Install sensor in the tank or flask and power on.

- Fill tank to required full level with required fuel.

- Remove calibration bung from sensor and use a suitable tool to depress PCB mounted calibration button. Hold for 5 seconds to set full point. Release button.

- Check full point and refit bung.

Empty Point (if required):

- Fill tank to required level or, for Min. Empty Level, remove from tank and shake to remove excess liquid.

- Disconnect power.

- Remove calibration bung from sensor and use a suitable tool to depress PCB mounted calibration button then reconnect power whilst depressing calibration button. Continue to depress for a further 5 seconds to set empty point. Release button.

- Check empty point and refit bung.

*These sensors cannot be installed inverted.