Description

General Specifications*

Temperature Range

Standard range is 40°F to 158°F,-40C to 70C.

Accuracy

Dependent on proper sizing of gauge and tank configuration. With direct reading dials, overall accuracy is ±5%; with TwinSiteTM Sender, ove- rall accuracy is ± 5%.

Current

TwinSiteTM versions, 200 mA. Maximum

Voltage

24 volts maximum nominal system voltage on TwinSiteTM versions.

Working Pressure

375 psig [25,8 Bar].

Approvals

Gauges are appropriately UL listed for LP Gas liquid-level service and/or LP Gas automotive accessories

When ordering, specify:

1.The tank inside diameter (shown on tank nameplate). 2. The mounting location (top, side, end or angle).

3.If the gauge is angle mounted state the degree of angle above or below the horizontal centerline.

4.If the gauge is end mounted, state the shape of the tank head (hemispherical or semi-ellipsoidal).

5.The ‘’H’’ dimension. This is the distance in inches from the surface of the tank to the top of the top threaded opening.

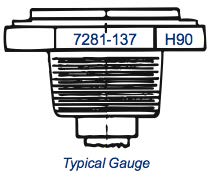

To order replacement gauge, simply furnish the information Stamped on one of the heads, as shown in the example.

Typical gauge head showing part number or tank code and Date code stamped on wrenching flats shown to the right.

Materials of Construction*

Head

Zinc die casting (7200 Series); brass forging (B7200 Series).

Centershaft Bearings, Gears, Pinion, Cross Stud & Bearing

Stainless Steel.

Gear Housing

Zinc die-casting or acetal.

Support, Centershaft & Float Rod

Tempered aluminum.

Float Bulb

Nitrile rubber or one-piece aluminum.

Counterweight

Lead.

Magnets

Alnico

Standard, Direct Reading Dials

Hermetically sealed polycarbonate.

Dial Screws

Stainless steel.

*Materials and specifications are subject to change without notice. Pressure ratings subject to change due to temperature and other

Environmental considerations.