Description

General Specifications

Active Sensing Range

15mm to 1000mm from flange

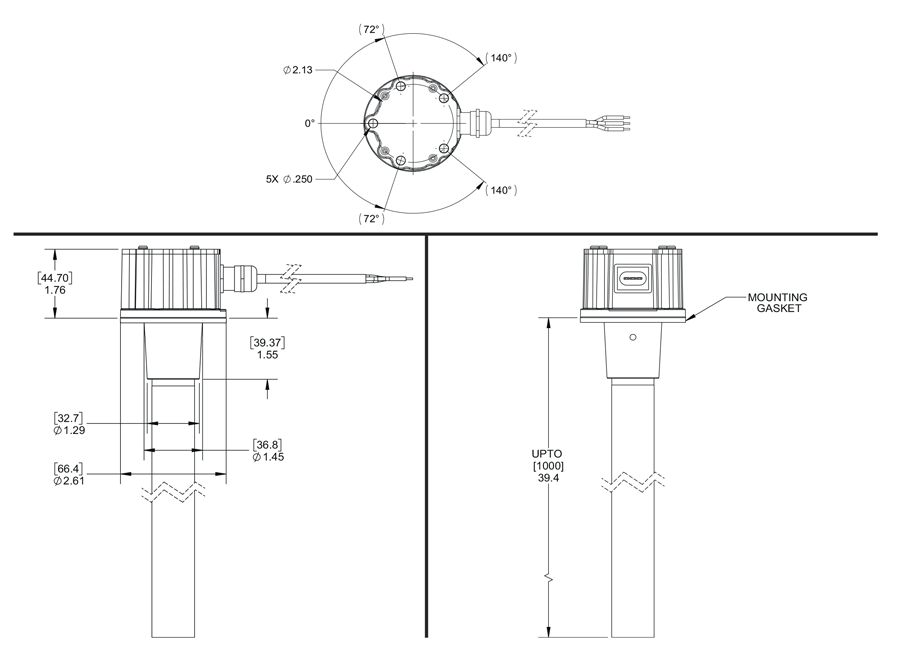

Housing Size

45mm (Height) x 67mm (diameter)

Connector

Configurable depending on output requirement

Operating and Storage Temperature Range

-40ºC to +105ºC

Water and Dust Sealing

IP69K

Maximum Tank Pressure

15 PSI

Shock

ISO 16750-3

Vibration

BS EN 60068-2-64: 1993 IEC 60068-2

Up to 500mm

Drop

ISO 16750-3

Surface Resistance

ISO 16750-3

Chemical Resistance

ISO 16750-5

Corrosion Resistance

VDA 621-415, DIN EN ISO 16270-2, DIN EN ISO 9227

Corrosive Gas Resistance

DIN 50018

Electrical Specifications

Supply Voltage

9-36 Vdc or 5Vdc regulated

Supply Current

35mA average

Superimposed AC over DC

ISO 16750-2

Supply Voltage Drop

ISO 16750-2 Section 4.6

EMC/EMI

UN ECE R10 revision 5

Output Specifications

Output Protocol

Analog – Voltage, PWM; Digital – LIN, CAN; Optional

programmable alarm output

Accuracy

±2.0% of span max (including nonlinearity,

hysteresis, temperature effects).

Resolution

1mm

Construction*

Housing

Die Cast Low Copper Aluminum

Sensor Tube

Extruded Low Copper Aluminum

Wetted Materials

Low Copper Aluminum, Buna Nitrile (or Viton), FR-4

Mounting Configuration

SAE 5 Bolt

Weight

Configurable including 5 and 6 bolt SAE

* Materials and specifications are subject to change with out notice. Pressure ratings subject to change due to temperature and other environmental considerations.